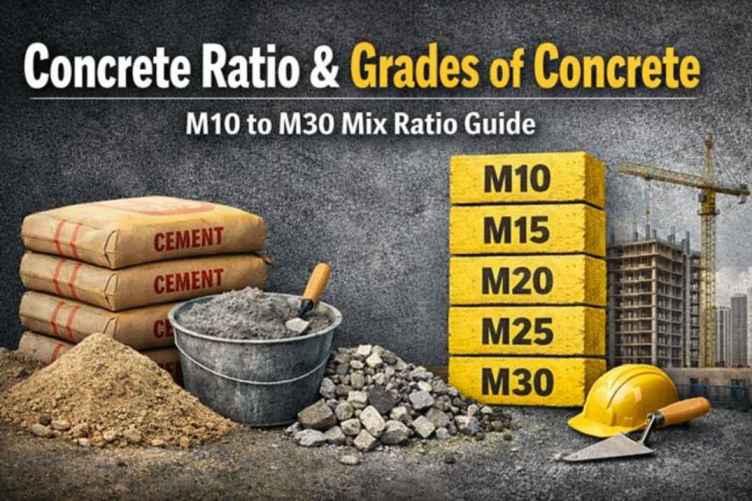

Concrete is the backbone of modern construction. Whether you are building a house, slab, column, beam, or foundation, choosing the correct concrete ratio and grade of concrete is very important for strength, durability, and safety.

In this guide by Omji Construction, we explain concrete mix ratios in simple language, covering M10, M15, M20, M25, and M30 concrete ratios, along with their uses in real construction work.

What is Concrete?

Concrete is a mixture of:

- Cement

- Sand (Fine Aggregate)

- Aggregate (Crushed Stone)

- Water

The proportion in which these materials are mixed is called the concrete mix ratio. This ratio directly affects the strength and quality of concrete.

What is Concrete Ratio?

Concrete ratio means the proportion of cement : sand : aggregate used in making concrete. For example, a ratio of 1:2:4 means:

- 1 part cement

- 2 parts sand

- 4 parts aggregate

Different construction works require different concrete ratios depending on load and structural needs.

What is Grade of Concrete?

The grade of concrete indicates the strength of concrete after 28 days of curing. Grades are written as M10, M15, M20, M25, M30, where “M” stands for Mix and the number shows strength in N/mm².

Higher grade concrete means higher strength and durability.

M10 Concrete Ratio

M10 concrete ratio is 1 : 3 : 6 (Cement : Sand : Aggregate).

Uses of M10 Concrete:

- Plain cement concrete (PCC)

- Levelling course

- Pathways and flooring base

M10 concrete is not used for structural work because of its low strength.

M15 Concrete Ratio

M15 concrete ratio is 1 : 2 : 4.

Uses of M15 Concrete:

- Flooring

- Footpaths

- Small residential works

M15 provides better strength than M10 but is still not recommended for RCC structures.

M20 Concrete Ratio

M20 concrete ratio is 1 : 1.5 : 3.

Uses of M20 Concrete:

- Residential slabs

- Beams and columns

- Footings

- RCC works

M20 is the minimum grade of concrete recommended for RCC in India as per IS standards.

M25 Concrete Ratio

M25 concrete ratio is 1 : 1 : 2.

Uses of M25 Concrete:

- Heavy-load slabs

- Commercial buildings

- Columns and beams with higher strength needs

M25 concrete offers higher durability and is commonly used in modern construction.

M30 Concrete Ratio

M30 concrete ratio is a design mix concrete, not fixed by simple volume ratios. It is prepared using batching plants.

Uses of M30 Concrete:

- High-rise buildings

- Bridges

- Heavy RCC structures

- Industrial construction

M30 concrete provides high strength, long life, and better resistance to environmental damage.

Concrete Mix Ratio Table

| Grade of Concrete | Concrete Ratio | Main Uses |

|---|---|---|

| M10 | 1 : 3 : 6 | PCC, base works |

| M15 | 1 : 2 : 4 | Flooring, paths |

| M20 | 1 : 1.5 : 3 | RCC slabs, beams |

| M25 | 1 : 1 : 2 | Commercial RCC |

| M30 | Design Mix | High-rise & industrial |

Which Concrete Grade Should You Use?

- For house construction: M20 or M25

- For flooring and PCC: M10 or M15

- For commercial projects: M25 or M30

Choosing the right grade of concrete ensures safety, strength, and long-term performance.

Conclusion

Understanding concrete ratio, concrete mix ratio, and grade of concrete is essential for any construction project. From M10 concrete ratio to M30 concrete ratio, each grade has its own purpose and strength.

For professional guidance and quality construction work in Jaipur and Rajasthan, trust Omji Construction — building strong foundations for a better future.